MAPPING

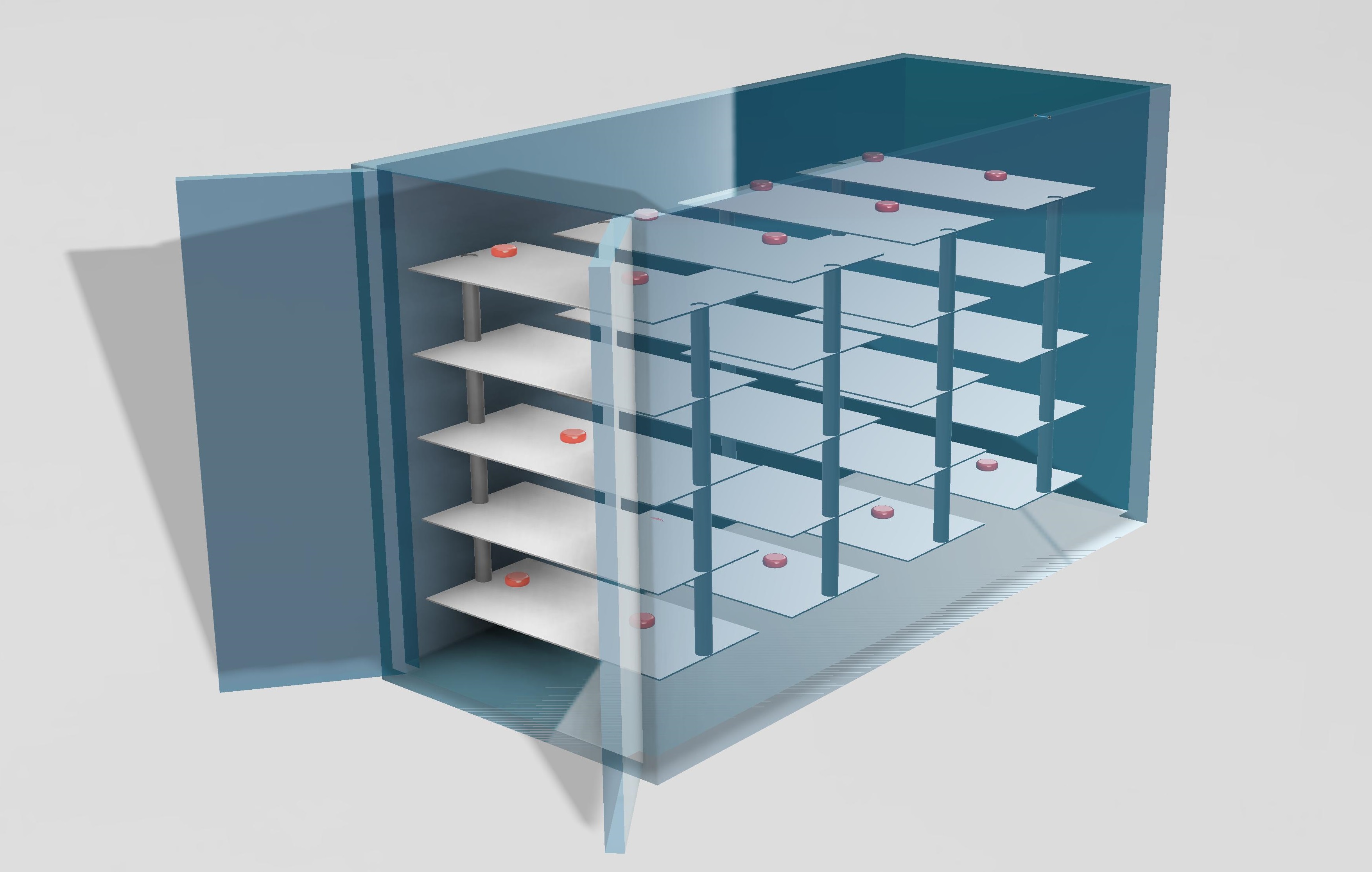

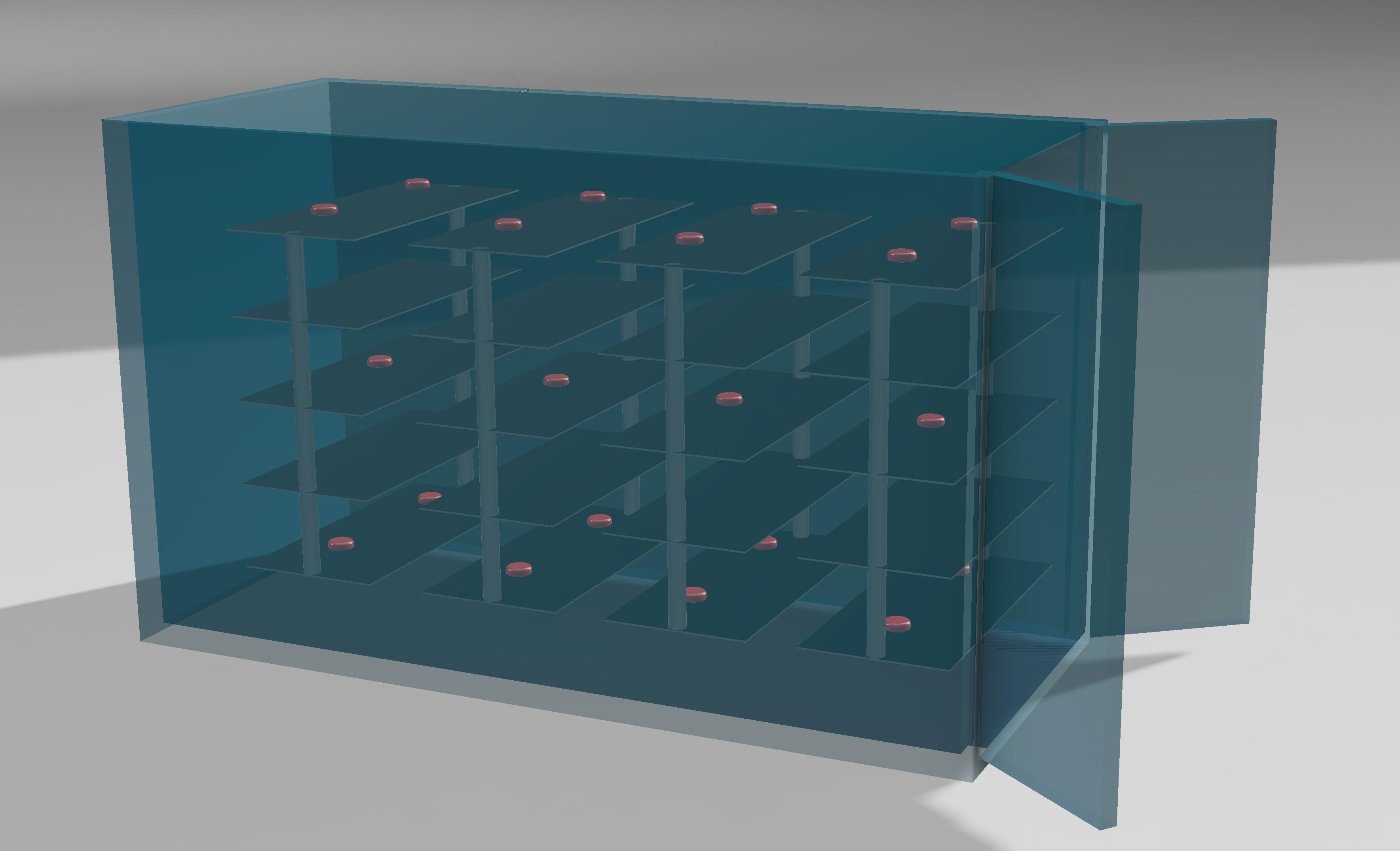

The mapping service is carried out by placing an adequate number of wireless temperature probes inside the client’s machinery and measuring the differences between the observed values while the machinery is active. These measurements are important in order to check the plant’s efficiency, taking corrective actions when needed.

There are three different types of measurements possible:

- with the empty machinery, to evaluate its homogeneity

- with the products inside the machinery, to evaluate the variations (different air flows happening, according to different placements of the products)

- on the surface of the products, using superficial and/or core temperature probes.

Depending on the type of machinery, there are different criticalities to be identified: cold points in ovens and warm points in cold storage rooms. For this reason, it’s important to elaborate a testing protocol for the mapping, considering these elements:

- type of mapping

- number and placement of probes

- measurement range and analysis duration

- limit values

- type of data necessary for the report.

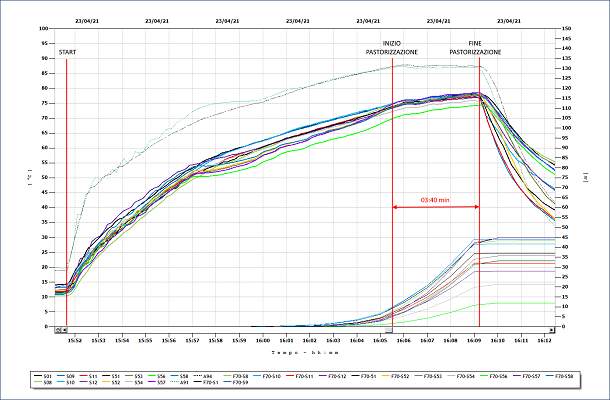

Probes are placed inside the machinery, which is brought up to a certain temperature. After the measuring, a diagram is generated. It has different trends, one on top of the other, showing the heat distribution inside the machinery and the time needed to reach that temperature. These data give information about:

- room temperature distribution;

- temperature difference between the setpoint and each measured point;

- C0 calculation (superficial cooking at 100°C/212°F with z=33) on the product surface;

- F value calculation (pasteurization at 70°C/158°F with z=10) on the product surface;

- core temperature variation.

WHY REQUIRE THE MAPPING SERVICE?

-

CRITICALITIES

Critical points inside the machinery are identified.

-

OPTIMIZATION

Cooking or cooling processes are optimized, allowing a correct placement of the products inside the machinery.

-

MAINTENANCE

Identification of the maintenance work that has to be done on the machinery.

-

QUALITY

Inhomogeneity issues are avoided, and that leads to a quality improvement, because products are treated correctly.